DMS PDMG-R Partial discharge monitor for EHV GIS

Continuous, real-time detection, alarming and analysis of partial discharge events

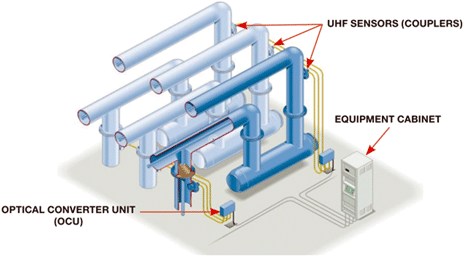

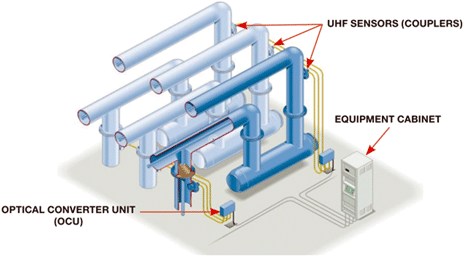

Utilizing advanced UHF technology, the PDMG–R system is designed for large EHV GIS installations. It collects PD data from UHF sensors (couplers) installed on the GIS and transmits the information to software for automatic interpretation and analysis by propriety HQ Software – allowing incipient faults to be avoided and the condition of the long term health of the insulation system to be simply and effectively monitored over the life of the GIS

UHF couplers installed throughout the gas insulated switchgear (GIS) detect partial discharge events and transmit these to an Optical Converter Unit (OCU) where the signal is conditioned and digitized before being transmitted to the Equipment Cabinet. Here proprietary algorithms are applied to correctly identify partial discharge events and reject interference from broadcast signals or discharges in adjacent air-insulated equipment. Detected partial discharge events are stored, flagged and alarmed allowing for timely corrective actions to be initiated. Remote access to all data allows GIS experts to assist in analysis and planning of actions at short notice.

Features:

- Automatic PD fault classification

- Robust design allows for reliable operation in almost any environment

- Flexible installation options

Applications:

The PDMG-R system is used for continuous, online partial discharge monitoring and analysis on permanently installed applications. For use on all makes of GIS in EHV transmission installations and on critical systems such as in power plants and large industrial consumers. Provides digital and analog (SCADA) outputs for remote alarm as well as remote data access to all diagnostic information.

QUALITROL Portable PDM Partial discharge monitor for transformers and GIS

Handy system for precise assessment of partial discharge during testing, commissioning and periodic inspections

A self sufficient and portable PDM system for rapid monitoring and analysis of partial discharge in gas insulated switchgear (GIS) and power transformers. The system is field operated, touch screen based and gives engineers the tools required for diagnosing partial discharge with limited or no access to the main PDM infrastructure.

Features:

- Full characterization and localization of partial discharge faults to determine the severity of PD and help in scheduling maintenance

- Very rapid and easy deployment enables maximum time for condition assessment of assets

- Robust and rugged design to maximize portable operation life and support inspections / testing for extended period of time (24 hours up to 12 months)

- Accurate fault detection improves reliability of HV testing ensuring safe and stable HV apparatus installed in substations

- HVDC compatibility saves cost of buying different PD testing equipment for HVDC apparatuses

- Advanced HMI provisions(SMARTSUB Software – intelligent data handling, display and interpretation)

- Intelligent customizable reporting

- Smart and quick real time alarming / alerting mechanism

- Expandable and field upgradable without reconfiguration

- Available in two versions; 3 channels (+1 noise channel) and 6 channels (+1 noise channel)

Applications:

- Used for low-cost, high performance periodic online and offline PD testing on HV insulating system of GIS and power transformers in transmission installations, power plants and large industrial consumers. The information gained from the system may be used for condition based maintenance decisions

- PD testing and analysis whilst installation and commissioning of HV GIS and transformers

- Quality testing for PD during or after assembling or manufacturing of GIS and transformers

- Lab measurements of PD on any insulating material for scientific and research laboratories

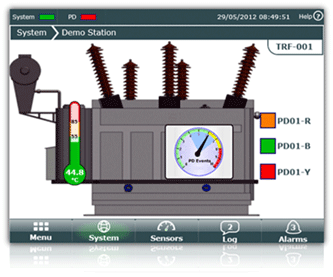

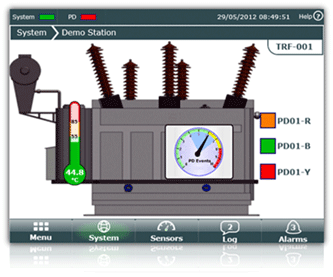

QUALITROL 609 PDM Transformer partial discharge monitor

Turn key condition monitoring solution to prevent costly failures and extend asset life of transformers

The 609 PDM system is an on-line partial discharge (PD) monitoring system for power transformers, based on industry accepted UHF technology.

Features:

- Accurate and early incipient fault detection ensures reliable operation and reduces supply outages

- Creates highly accurate reports on asset condition hence reduces maintenance costs

- Monitors multiple transformers simultaneously resulting in higher return on investment

- Robust design and excellent interference immunity for measurements under difficult environmental conditions

- Advanced HMI provisions(intelligent data handling, display and interpretation)

- Qualitrol Expert PD analysis services

- Flexible installation and configuration options to meet customer expectations

- Smart and quick real time alarming / alerting mechanism

- Remote monitoring and configuration

- Expandable and field upgradable without reconfiguration

Application:

The 609 PDM is used to continuously assess the performance of insulation in a power transformers so that corrective actions can be taken before any failure occurs. The information gained from the system is used for condition based maintenance decisions to optimize maintenance expenditure.

TWS MkVI Traveling wave fault locator

Provides exact fault location to one span

Features:

- Accurate and early incipient fault detection ensures reliable operation and reduces supply outages

- Creates highly accurate reports on asset condition hence reduces maintenance costs

- Monitors multiple transformers simultaneously resulting in higher return on investment

- Robust design and excellent interference immunity for measurements under difficult environmental conditions

- Advanced HMI provisions(intelligent data handling, display and interpretation)

- Qualitrol Expert PD analysis services

- Flexible installation and configuration options to meet customer expectations

- Smart and quick real time alarming / alerting mechanism

- Remote monitoring and configuration

- Expandable and field upgradable without reconfiguration

Application:

The 609 PDM is used to continuously assess the performance of insulation in a power transformers so that corrective actions can be taken before any failure occurs. The information gained from the system is used for condition based maintenance decisions to optimize maintenance expenditure.

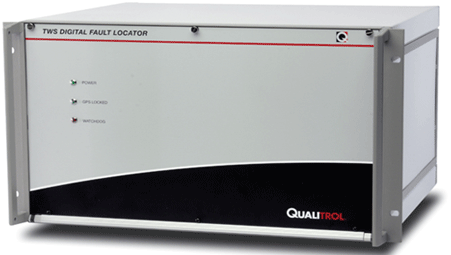

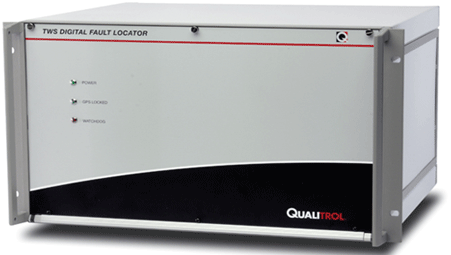

TWS MkVI Traveling wave fault locator

Provides exact fault location to one span

A device that provides extremely precise fault location on mulitple lines enabling operation and maintenance engineers to respond rapidly to events to correct defects at minimum cost and maximum efficiency.

7 ways TWS can save time and money and improve reliability:

- Reduce line patrol manpower costs

- Reduce aerial patrol costs

- Prevent re-occuring faults

- Reduce power quality impact of ‘preventable faults’

- Eliminate separate substation clock

- Reduce costs to maintain system security during line outage

- Reduce cost of regulatory fines due to power outage

Features:

- Accuracy to ±500 feet (±150 meters) independent of impedance methods

- Reduce downtime by getting to the fault site faster

- Track intermittent self clearing faults and focus maintenance at the right spot to prevent a major breakdown

- Results automatically displayed and e-mailed

- Fast installation and set up on multiple lines – no line or substation outage required

- Modular, reliable hardware

- Flexible communications

- Up to 8 line modules to monitor up to 8 circuits

- GPS card, pulse output – optional 1pps or 1ppm selectable

Application:

Fault location on interconnected overhead lines where high reliability is important. Accurate,consistent results for all types of faults quickly displayed in a control room or engineering center where the information is needed to direct maintenance teams and reduce downtime.

TWS FL-8 and TWS FL-1 Traveling wave fault locators

Provides exact fault location to one tower – improved performance

A device that provides extremely precise fault location on multiple lines enabling operation and maintenance engineers to respond rapidly to events and correct defects at minimum cost and maximum efficiency.

Features:

- Best accuracy to ±195 feet [±60 meters] independent of impedance methods

- Reduce downtime by getting to the fault site faster

- Track intermittent self clearing faults and focus maintenance at the right spot to prevent a major breakdown

- Maintenance crews alerted by email notification

- Fast installation and set up on multiple lines – no line or substation outage required

- Display, keypad and USB port allow more interaction with the device

- Modular, reliable hardware

- Flexible communications

- Monitor 2, 4, 6, or 8 lines (TWS FL-8)

Application:

Fault location on interconnected overhead lines where high availability is important. Accurate, consistent results for all types of faults quickly displayed in a control room or engineering centre where it is needed to direct maintenance teams and reduce downtime

QUALITROL T/Guard 408 and 408XT Fiber optic temperature monitoring system

Real time direct winding optical temperature monitoring system

Rugged multi-channel fiber optic real-time hot spot monitoring system for dry-type and oil-filled transformers.

Features:

- Provide essential data during transformer heat run

- Maximize cooling efficiency with accurate hot spot temperature measurement

- Optimize loading dynamically without compromising transformer life

- Complements predictive hot-spot algorithm simulations

- Compatible with Qualitrol Q-Link™ for Apple® iPhone®, OptiLink and OptiLink-II

- Available with 4, 6, 8, 10, 12 or 16 channels

Features:

Local monitoring of oil-filled transformer and load tap changer with Qualitrol T2 temperature probes.

Direct Winding Transformer Monitor Accessories

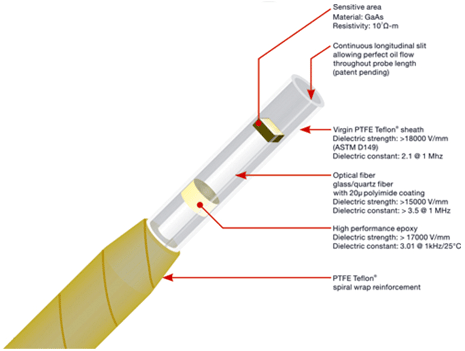

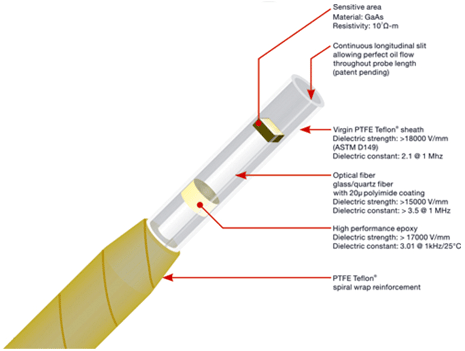

QUALITROL CAB-699 Fiber optic temperature probe

Field proven high accuracy probe for measuring hot spot temperature

Robust, oil-permeable Neoptix T2™ temperature probes for highly accurate measurement of power transformer temperatures. Installed within standard spacer or directly onto any other location inside transformer windings to directly measure ‘hot spot’ temperature.

Features:

- Direct measurement inside transformer yields highly temperature readings reducing risk of failure or unnecessary reduction in transformer life

- Over 35,000 installed worldwide

- Long term, drift-free survivability

- All materials are chemically and dielectrically resistant

- ST type connectors resist failure due to vibration

- Does not require recalibration or complex input to operate

- Galium arsenide (GaAs) measurement principle

- Surpasses ASTM dielectric strength standards for use inside transformers

- Unique, patent-pending longitudinal slit enables uniform contact with transformer oil over entire probe length

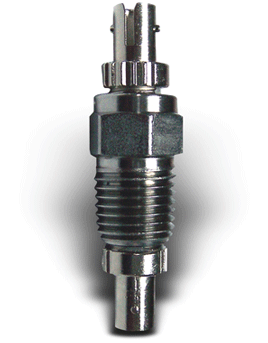

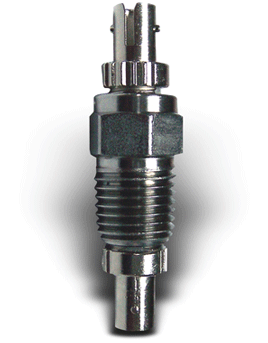

QUALITROL CON-159 Optical feedthrough

Leak-free transformer tank wall feedthrough

Provides leak-free, long term connection between the inside fiber probe (CAB-699) and outside extension cable (CAB-700) through transformer tank walls. Designed to mate with other QUALITROL direct winding transformer accessories.

Features:

- Glass-to-metal bonding technique insures no leaking between feedthrough connector and inside of transformer tank

- Glass-to-metal bonding eliminates need for epoxy bonding or O-rings, which require maintenance and tend to fail

- Hundreds have been installed over time with not even one reported leak

- Made standard with 1/4 inch NPT male bulkhead, 18 ANSI threads per inch

- Insures proper probe installation

- Enables probe installation without carrying bulky mechanical weight at probe end Reduces chances of probe breakage during installation

- ST type connectors resist failure due to vibration

- Can be mounted anywhere

- Designed specifically for oil filled or dry-type transformers; can be mounted on any part or location on transformer

- Survives full vacuum or pressure (up to 200 psi)

QUALITROL COV-121/PLT-201/PLT-202 Junction box for tank wall plate

Reliable protection of fiber optic connections

Designed for prolonged protection of fiber optic components in any environment. Removable panel for easy access to connections without removal of entire junction box and conduit. Tank wall plates available in bolt-on (PLT-202) and weld-on (PLT-201) versions. Number of holes in tank wall plate are customer specified and designed to mate with optical feedthroughs (CON-159-1).

Features:

Reliable protection of fiber optic connections

- Eliminates need for drilling additional holes or welding to create a ‘do-it-yourself’ solution for protection of fiber optic connections

- Two specially designed 1/8 inch (3.2mm) thick neoprene gaskets (one for access panel and one for base of junction box) isolate optical feedthroughs (CON-159-1) and fiber optic extension cables (CAB-700) from harsh environmental conditions

Easy installation

- Access panel makes installation and connections easy

- Flat surface for quick, easy and leak-free conduit installation

Junction box mates with all QUALITROL tank wall plates

- Junction box designed to perfectly mate with either bolt-on (PLT-202) or weld-on (PLT-201) tank wall plates

QUALITROL KIT-057 Portable fiber optic thermometer

Compact fiber optic temperature measurement

Single channel fiber optic thermometer with large, backlit LCD display. Battery (standard AA batteries) or universal power supply operation. Can log data onto SD flash card (2GB max) or directly to laptop using OptiLink™ software.

Features:

Compact fiber optic temperature measurement

- Fits in hand, battery operated

- Rugged casing for every day field and factory use

Easily verify probes throughout installation

- Maximum user freedom to measure temperature at many critical sensing points

- No calibration between probes (saves time

Fully functional through front interface

- Instrument set up and configuration, data logging on SD card and expert mode all accessible through display menu

- 160 x 160 pixel LCD display with LED backlight

Highly accurate across wide temperature ranges

- Accuracy within ± 0.5°C

- Operates from -20°C to 65°C (-4°F to 149°F) ambient temperature

Captures measurements for later review

- Data can be saved onto high capacity SD flash card for access through any PC with flash card reader

- Datalogging can also be accomplished through OptiLink ™ directly to computer hard disk

- SnapLog ™ feature enables recording of one temperature point with time stamp at the press of a button